Micro-Dwelling

Designed a micro-dwelling for homeless people in the New England Upper Valley in the Structural Analysis (ENGS 71) course at Dartmouth

Overview

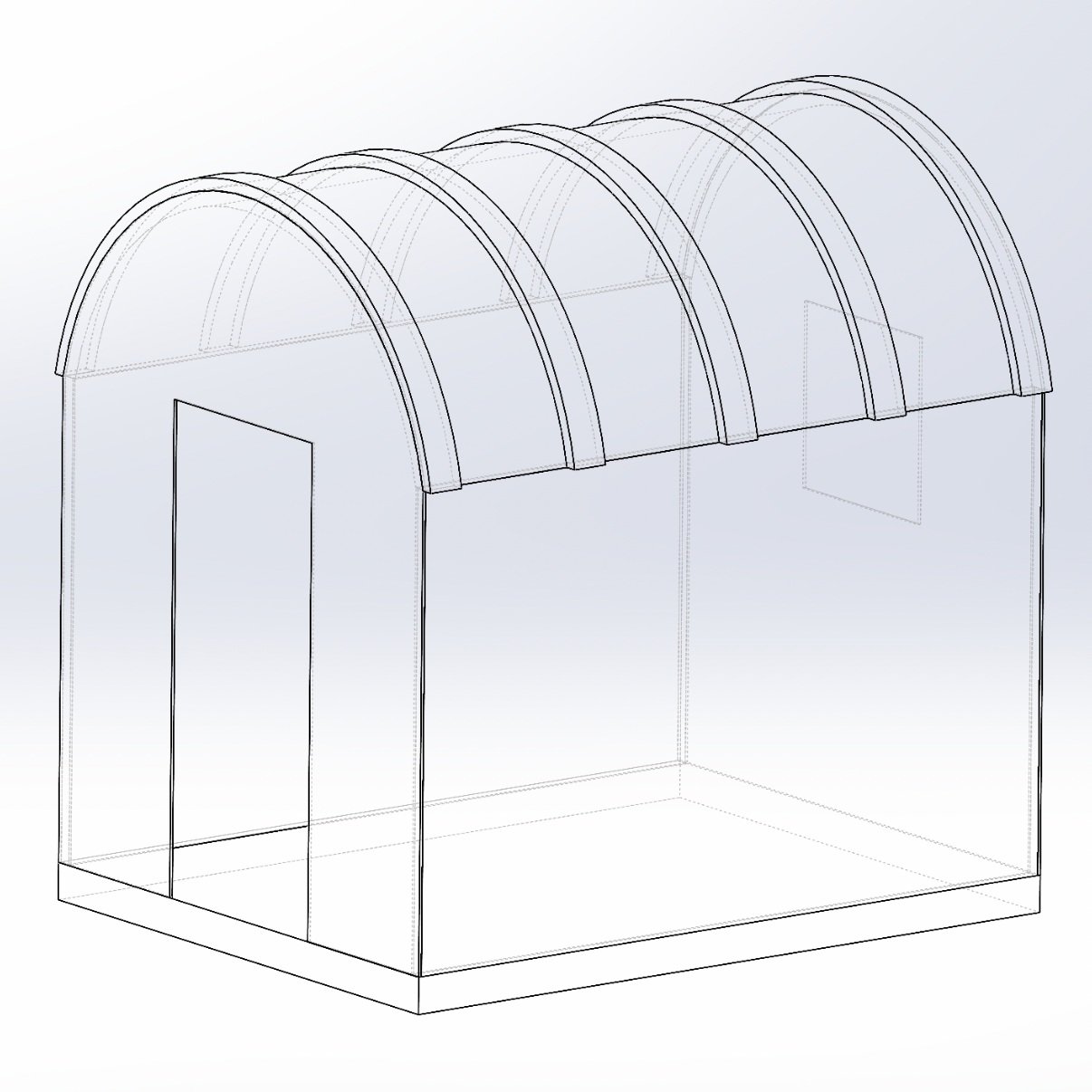

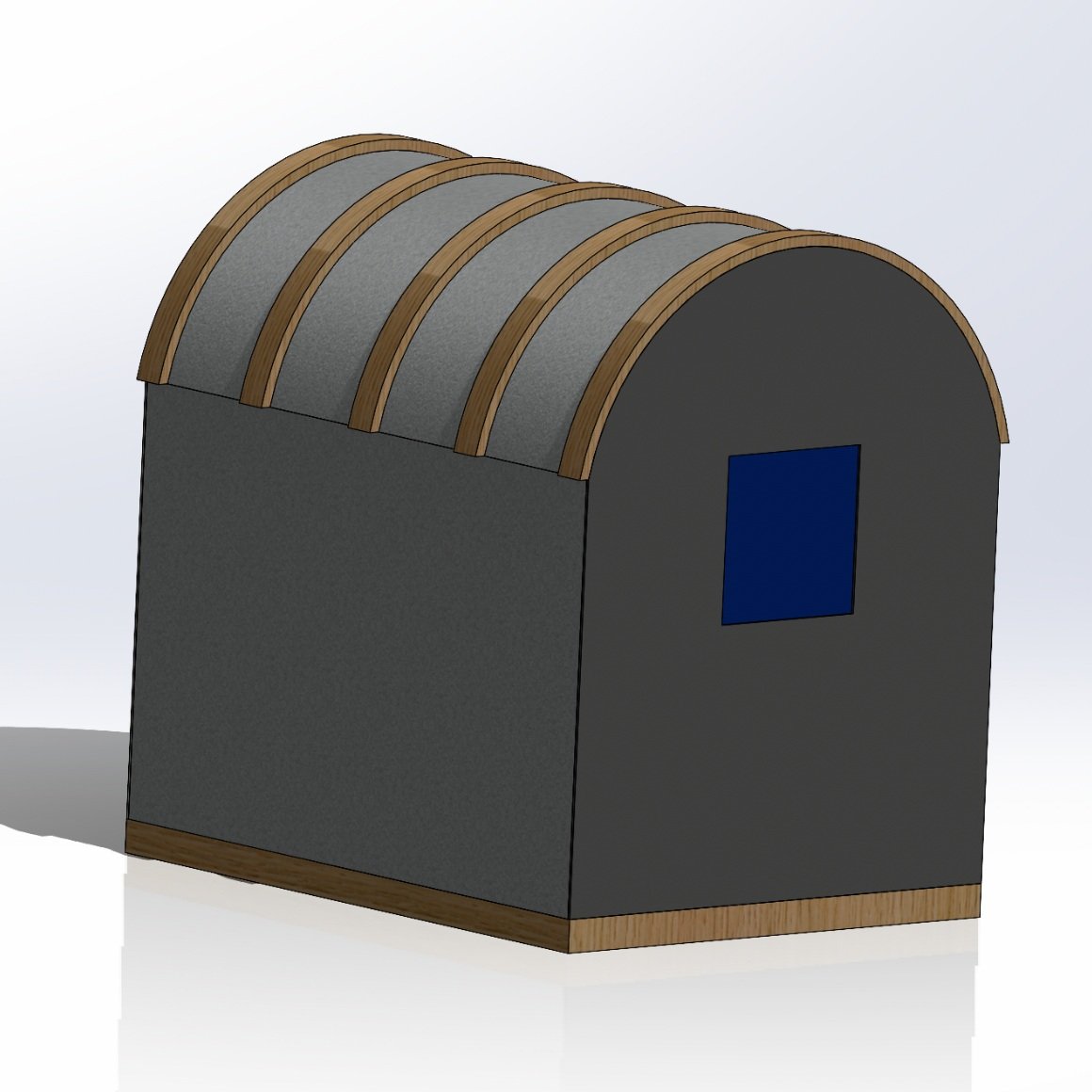

My project group consisted of 4 people, including me, and our chosen focus was the roof of the micro dwelling. The walls of the dwelling that we were working with were 2-inch foam with drywall on the outside. We researched various types of roofs and roof materials before jumping into the modeling and prototyping phase using SolidWorks. We also performed FEA analyses on our final SolidWorks prototype. Work was split evenly throughout, so I was involved in all aspects of the process.

Design Considerations

Below is a summary of some of our design considerations while prototyping:

The angle between the walls and the roof should be optimized using joinery.

Previously, spray foam was the standard for connections; we looked into mechanical fixture as well (teeth, nails, nuts and bolts).

Drywall would be stiff enough to drill through.

Joinery should also be weather-resistant. It cannot expand or contract with temperature or rust with water.

The dome should not cave in or sag, potential bending under different loads should be analyzed using FEA on SolidWorks.

The Upper Valley has a snow-prone climate. The slope of the roof should be optimized so that it’s neither too steep (could cause great amounts of snow or ice to slide off at once) nor too shallow (if the slip angle is not met, the snow sitting on top of the roof would increase the dead weight of the roof).

Most insulation should be ensured by taking advantage of different materials and architecture strategies.

Stability of the roof should be weighed against the easy disassembly that we are trying to ensure.

Laths are great for strength and stability but are difficult to deconstruct.

This is an independent voluntary project so our design should be cheap, accessible, and simple to construct.

Keeping in mind the above considerations, we researched and experimented with the following roof types:

Curved Roof— difficult to manufacture

Vaulted Roof— difficult to construct and deconstruct

Shed Roof— has too much bending

Gable Roof— difficult to stabilize

Ultimately we went with the curved roof design because of the relatively low requirements for maintenance, the fact that arched roofs are mostly self-supporting up to a certain-width, the ease of construction, and the easy customizability of the design based on the criteria we want to meet.